Evonik’s animal feed solutions boost feed efficiency and livestock productivity, ethically and sustainably.

Introduction

With rising feed prices and high energy costs, the global livestock industry – like many others – is feeling the pinch. Higher input costs and production expenses, supply chain challenges and adverse weather conditions are all contributing to the increasing cost of livestock production, squeezing farmers’ already tight margins further.

These record prices are pushing up costs for the consumer, too, via more expensive animal products and produce. It is an issue that affects the whole value chain. Given the impact of rising feed prices on the overall cost of production, keeping costs to a minimum while maintaining animal health, performance and productivity is vital.

Supplementing animals’ diets with amino acids (AA), such as DL-Methionine, offers a viable and effective route to achieving maximum productivity at the least cost and, consequently, improving the bottom line.

The challenge: Keeping production cost low

Today, livestock producers are under pressure to improve performance, keep animals healthy and lower their environmental footprint – all while remaining competitive and profitable. It can be a difficult juggling act in good economic times, let alone during periods of volatility. For those in the global animal agriculture industry, it is not enough to survive in today’s market, they need to thrive.

Feed has always been and remains the most significant cost of livestock production, representing as much as 60 to 70 percent of overall costs. Therefore, any change in feed management strategies can have a great impact on farm profitability, since everything that goes into feed formulation affects the bottom line. With the growing pressure on farmers’ budgets and diminishing margins, optimizing costs is an essential part of any strategy.

This is where effective AA supplementation comes into play. Given all feed sources vary in their AA content, adding AAs to diets means livestock producers can formulate, with precision, the optimal nutritionally balanced feed for their animals to improve nutrient absorption, energy utilization, growth performance and yield.

Methionine is an essential amino acid that plays an important role in metabolism and the synthesis of tissue, vitamins, hormones and enzymes. It is therefore commonly used in animal feed formulations worldwide, with demand for methionine growing across the globe in line with the increasing demand for animal protein products from an expanding population.

In broilers, both Met and cysteine (Cys) are the amino acids in shortest supply and therefore the first to become deficient in the animal’s diet. The levels needed by the bird cannot be met from natural sources alone, and absence or undersupply can be very detrimental to performance. Therefore, methionine supplementation is needed to balance the dietary total sulphur-amino acids (TSAA) in broiler diets.

In the market, commercial methionine sources available include DL-Methionine (DL-Met)and liquid Methionine Hydroxy Analogue-Free Acid (MHA-FA) – but they do differ.

Whereas DL-Met is the exact amino acid Met in dry form with almost 100 % purity, MHA-FA is not an amino acid but an acid in liquid form (from a chemical point of view), and so after biochemical conversion it can only, at best, exert an AA effect. It has been demonstrated in numerous studies and trials that liquid MHA is a less effective source of methionine than DL-Met.

As methionine is considered an essential ingredient in animal feed management, knowing the best product is key, especially when cost-saving is required.

Better nutritional value

Many studies and scientific publications have shown that the biological efficiency of MHA-FA is 65 percent compared to DL-Met (Elwert et al. 2008, Lemme et al. 2012, EFSA 2018). This matters, because to overestimate the nutritional value of MHA-FA can be detrimental to growth and performance as the animal ends up getting less methionine from its food than assumed.

In a recent study conducted at the Research Facility of Al-Estesharia for Poultry and Feed in Jordan, researchers sought to demonstrate that each 1 kg of MHA-FA added to broiler chickens’ diets could be replaced with only 650 g DL-Met in both below-requirement and at-requirement doses, with no adverse effect on bird performance. They also wanted to prove that both methionine-supplemented diets would produce better bird performance than a Met-deficient diet.

The study involved 2,500 day-old broiler chickens (50% male and 50% female) randomly distributed into five treatments, with 10 replicates per treatment. The birds were given pelleted feed and all pens were supplied with two feeders, water nipples and cup drinkers.

The birds were fed one of three experimental diets during the starter, grower and finisher phases, with all diets formulated to meet the nutrients requirements except for Met+Cys (Table 2).

- T1: Control group with no supplemental methionine sources

- T2: Standard MHA current Jordanian nutrient levels, MHA-FA supplemented considering 65% of Met and or M+C

- T3: Standard DLM (as for T4), but MHA-FA replaced using DL-Met at 65% BE (weight to weight basis).

Table 2: Experimental diets

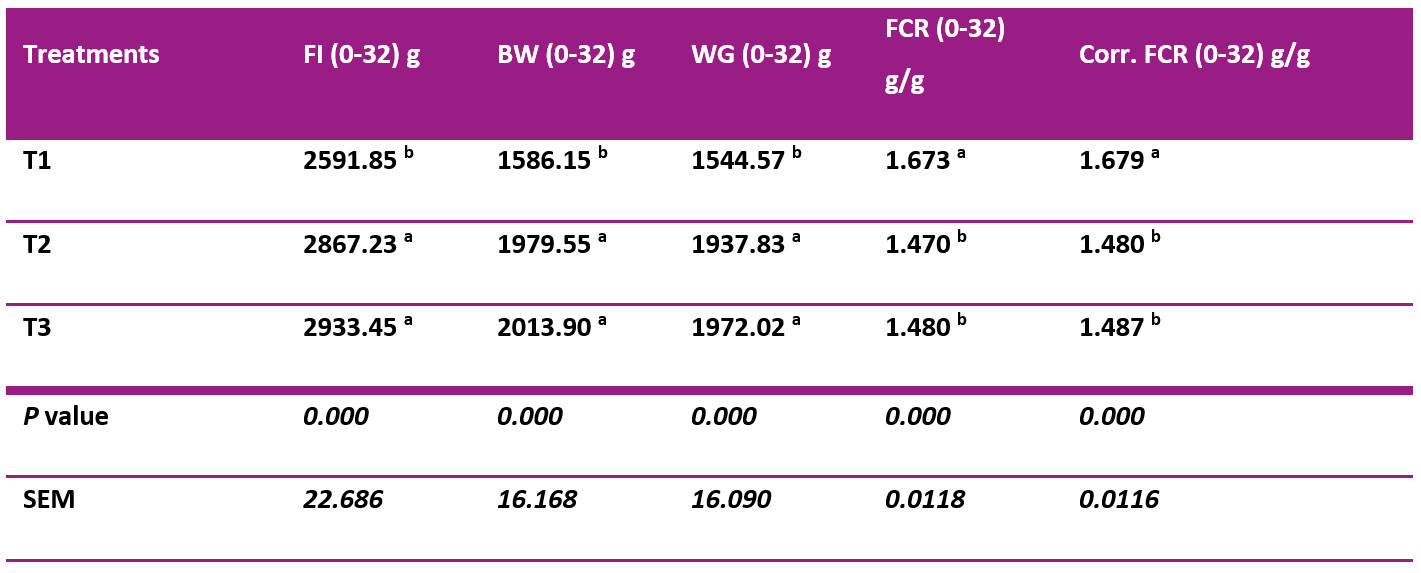

To measure and analyze growth performance, they assessed Feed Intake (FI), Body Weight (BW), Weight Gain (WG), Feed Conversion Ratio (FCR), Feed Conversion Ratio Corrected for Mortality (Corr. FCR) and Mortality (recorded daily, both weight and number).

How DL-Met reduces feed cost

During the trial, the case for methionine supplementation was clear. In general, the performance of all birds fed methionine-adequate diets was in line with breed expectations (Ross 308, 2019). Birds fed diets containing no additional methionine supplementation, however, achieved a lower body weight and had a higher FCR.

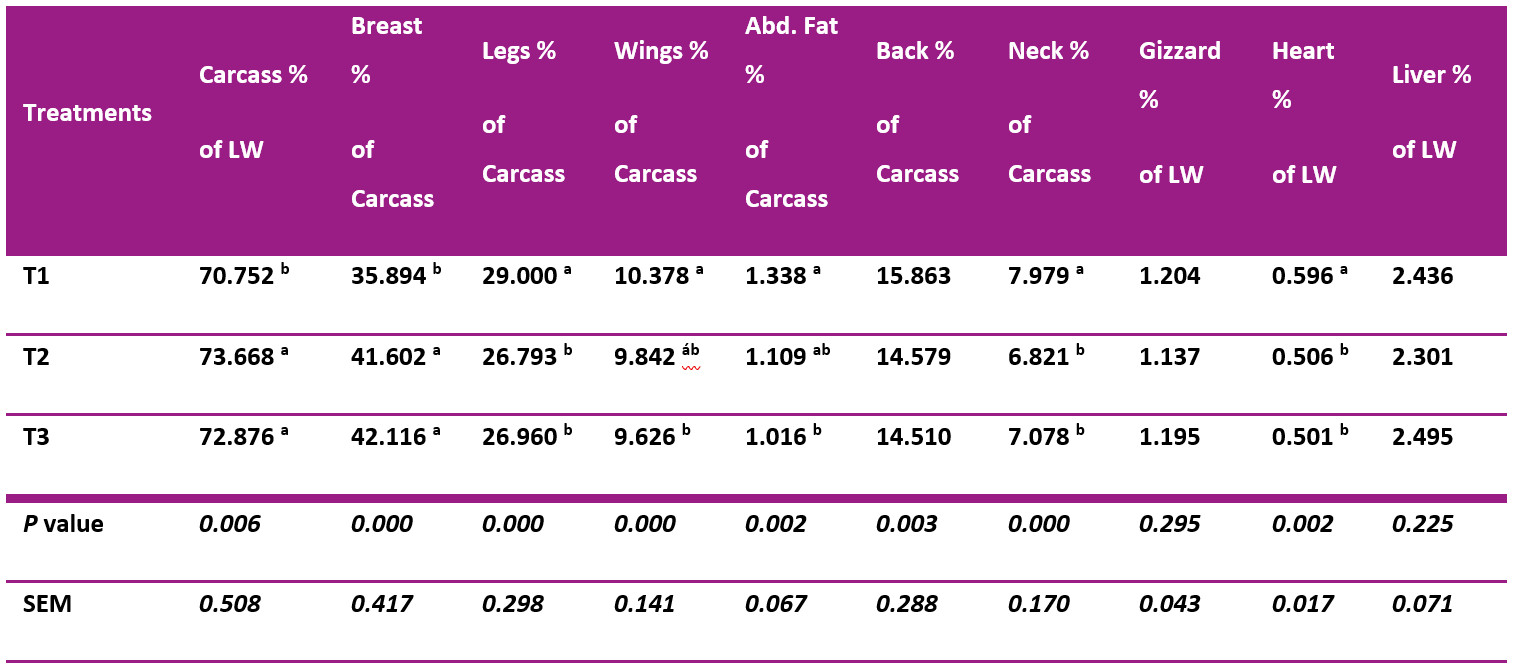

The effect the two methionine sources had on growth performance and carcass parameters are shown in Table 3 and Table 4.

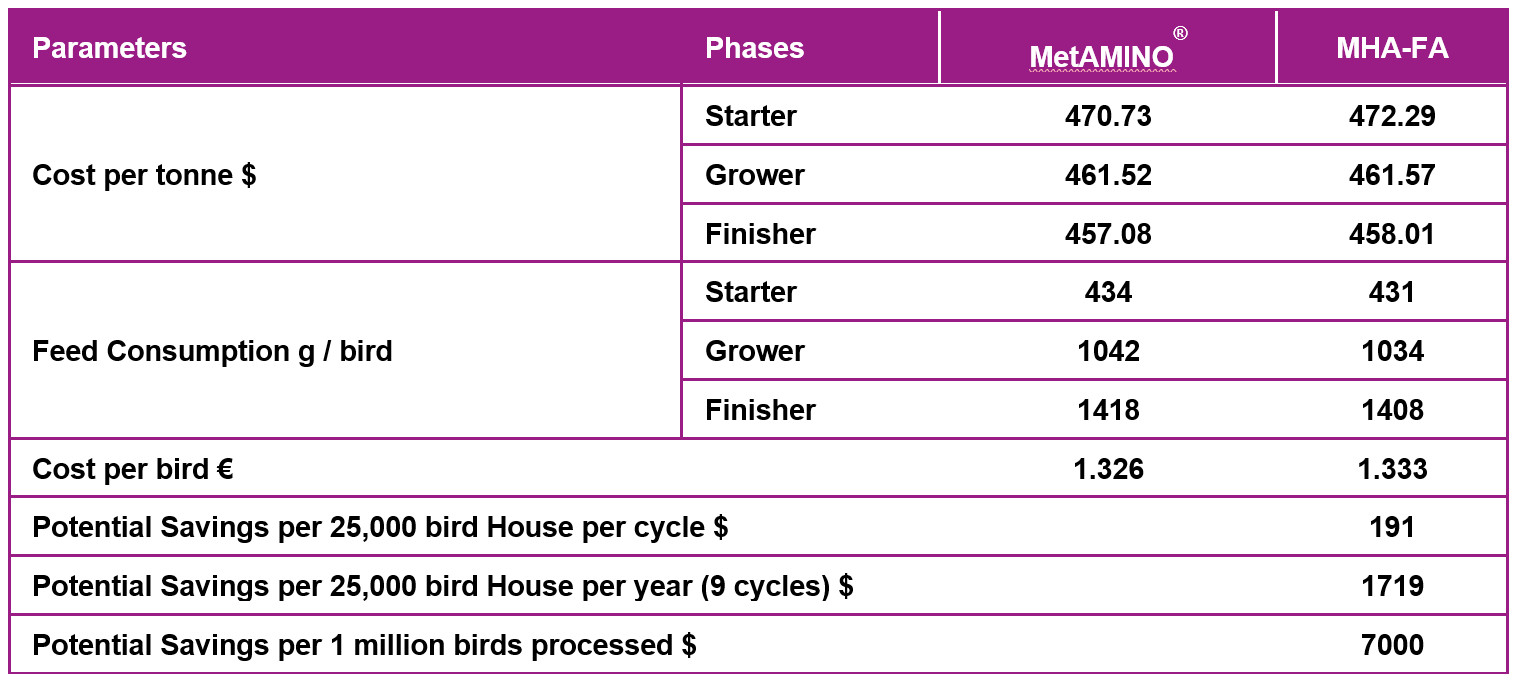

Moreover, the results showed there were no differences in performance when replacing MHA-FA with DL-Met in a ratio of 100:65, underlining that this concept works and DL-Met can ensure consistent and high performance, as well as cost savings. The study therefore found that the use of DL-Met compared to MHA-FA resulted in reduced feed cost and thus, increased profitability (Table 4). Reducing the feed amino acid specification by 25 % also leads exactly to the same outcome when replacing MHA-FA with DL-Met in a ratio of 100:65.

Table 3: Carcass parameters

Feed cost

When it comes to methionine supplementation, precision is key. From previous studies, it is known that DL-Met has an ileal digestibility of 100%. Therefore, in principle, the entire amount of DL-Met added to the diet is available to the broiler for protein synthesis, meaning none is wasted.

With proven results in ensuring efficient protein synthesis, DL-Met should be the go-to product for livestock producers. Thanks to its high purity (99%) and 100% bioefficacy, producers can achieve the best results with Evonik’s MetAMINO®, which offers unsurpassed quality.

MetAMINO® enables superior meat yield and feed conversion while offering easier management of dosing and handling. Its dry form means it can be added to feed at any point during the mixing process and at any temperature, unlike liquid forms. It is also non-corrosive and so poses no damage to mill equipment. Moreover, MetAMINO® supports sustainable farming initiatives as it leads to reductions in nitrogen excretions and carbon footprint.

Complementary services can also be utilized to maximize the effectiveness of such an approach. Tools such as AMINONIR®, which offers fast and reliable nutritional analysis of feed raw materials, and AMINODat®, Evonik’s database of more than 28,000 feed samples, can equip producers with the data and knowledge they need to finetune their animals’ diet for optimal performance, and ensure improved quality, less waste and smoother processes.

Taken together, these products and services support livestock health and performance and enable producers to run a high-productivity, low-cost operation.

Table 4: Economics

Conclusion

As has been demonstrated, the use of DL-Met as an M+C source compared to MHA-FA-supplemented feed resulted in reduced feed cost without affecting bird performance. It can therefore be concluded that irrespective of Met dosage in both below-requirement and at-requirement doses, each 1 kg of MHA-FA can be successfully replaced by only 650g DL-Met, to improve profitability.

In conclusion, supplementing animal diets with DL-Met, such as MetAMINO®, can provide a viable and sustainable solution for livestock producers to achieve optimal performance results while realising substantial savings in feed costs – and, subsequently, lower the overall cost and environmental impact of production.

This article was first published in: WATTPoultry June 1, 2023

The content of this document is for the information and assistance of Evonik’s customers and is not applicable to products marketed or sold in the United States. Evonik markets its products in compliance with applicable local laws, but it is the user’s responsibility to ensure that the use of and any claims made for this product comply with all relevant requirements. This document may not be published in the United States without the express written consent of Evonik Operations.